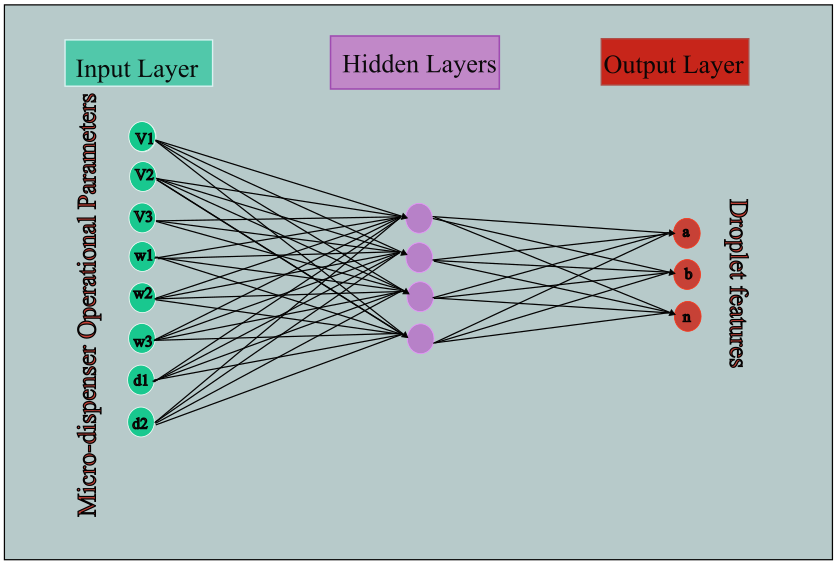

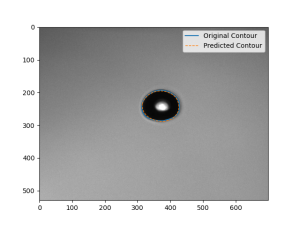

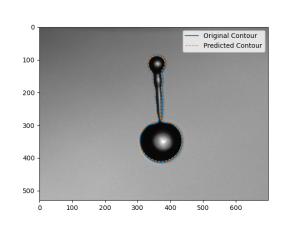

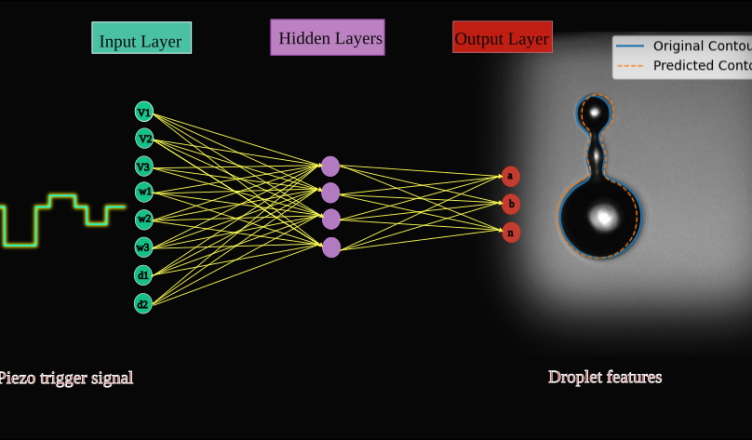

The growing significance of ink-jet printing in modern manufacturing is underscored by the critical need to understand how droplet characteristics are influenced by operational parameters and ink properties. Accurate modeling of real-world conditions is deemed essential for refining operational settings. Therefore, in this study, the intricate connections between operational settings, ink properties, and droplet characteristics are explored. Utilizing the Microdrop MD-E-5000 experimental setup, equipped with a micro-dispenser head, droplets were generated under various operational conditions. This process involved the emission of three pulses, each characterized by voltage, pulse width, and inter-pulse time. Subsequent image processing using the OpenCV library enabled droplet counting and extraction of geometric features. These features, encompassing droplet geometry, were compiled into an HDF5 database, laying the groundwork for machine learning training. The ultimate objective is to train a neural network capable of rapidly predicting printing outcomes by leveraging these droplet features. Through this approach, predictive models are being developed to capture droplet shapes by delineating the contours enclosing droplets emitted by the micro-dispenser.