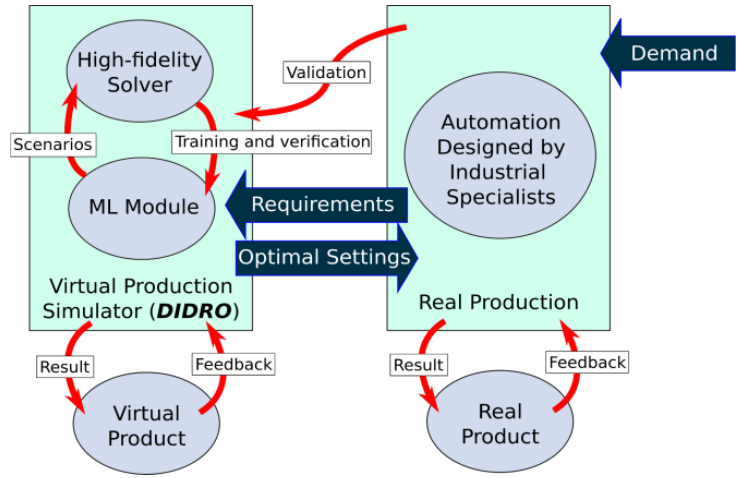

The goal of DIDRO project is to make a step towards developing a Digital Twin of an inkjet-printer for

manufacturing purposes. It focuses on developing and implementing a numerical model that simulates

the process of ink ejection from the nozzle and its final configuration associated to its eventual spreading

on the solid surface. The model is based on an enriched Finite Element/Level Set method. In order to

facilitate quick predictions, a Machine Learning algorithm (possibly, based on Gaussian process) will be

developed and implemented that shall be able to recognize different droplet/jet ejection modes based on

the knowledge of the printing parameters. Inkjet printing simulations and code validation will have to be

carried out.

Project Objectives

Towards establishing a robust digital twin for drop-on-demand inkjet manufacturing, DIDRO set out to:

- General objective: Develop and implement a virtual tool with rapid predictive capabilities to form the core of a digital twin for inkjet-based processes, enabling industrial specialists to adjust printing regimes, nozzle configurations and ink formulations in real time to guarantee product quality.

- Specific objectives:

- Formulate the governing equations for the key physical phenomena in inkjet droplet generation.

- Implement these physics in an efficient, coupled multiphysics solver within an open-source framework.

- Generate representative numerical data via high-fidelity simulations for benchmarking.

- Establish a machine-learning methodology to deliver “fast” industry-ready predictions of inkjet behavior.

Key Achievements & Resources

- Digital Twin Prototype

- High-fidelity multiphysics core coupled with an AI optimization loop for real-time parameter tuning.

- In-House Experimental Platform

- Over 1 000 000 individual“drop-on-demand” trials to systematically explore the functionality of the inkjet dispenser with different configuration of operational parameters.

- Open Dataset on Zenodo

- Comprehensive, curated dataset (cleaned raw measurements + derived post-processed results) of > 300 000 experiments.

- Available under Creative Commons:

https://doi.org/10.5281/zenodo.13862494

- Open-Source Analysis Pipelines

- CFD enhancements contributed to Kratos Multiphysics’ DropletDynamicsApplication module:

https://github.com/KratosMultiphysics/Kratos - Image processing:

https://github.com/DropletDynamics/MorphoContour - Dispenser driving and experimental data analysis scripts:

https://github.com/DropletDynamics/InkJetDroplet - machine-learning code (with trained models and droplet-prediction algorithms):

https://github.com/DropletDynamics/EllipseAI_PredictDroplets

- CFD enhancements contributed to Kratos Multiphysics’ DropletDynamicsApplication module:

- High-Impact Publications

- Eight peer-reviewed articles (IF 2.6–9.7, avg. 6.0) in Q1 journals.

- Hashemi, A., Hashemi, M. R., Ryzhakov, P., & Rossi, R. (2024). Optimization-based level-set re-initialization: A robust interface preserving approach in multiphase problems. Computer Methods in Applied Mechanics and Engineering, 420, 116699. https://doi.org/10.1016/j.cma.2023.116699 IF(2022): 7.6

- Narváez-Muñoz, C., Hashemi, M. R., Ryzhakov, P., Pons-Prats, J., & Owen, H. (2023). Enriched finite element approach for modeling discontinuous electric field in multi-material problems. Finite Elements in Analysis and Design, 225, 104007. https://doi.org/10.1016/j.finel.2023.104007 IF(2022): 3.1

- Narváez-Muñoz, C., Hashemi, M. R., Ryzhakov, P. B., & Pons-Prats, J. (2023). An enriched finite element/level-set model for two-phase electrohydrodynamic simulations. Physics of Fluids, 35(1), 012004. https://doi.org/10.1063/5.0127274. IF(2022): 4.6

- Narváez-Muñoz, C., Hashemi, A., Hashemi, M. R., Segura, L. J., & Ryzhakov, P. (2024). Computational electrohydrodynamics in microsystems: A review of challenges and applications. Archives of Computational Methods in Engineering. https://doi.org/10.1007/s11831-024-10147-x IF(2022): 9.7

- Ares de Parga-Regalado, A. M., Hashemi, A., & Ryzhakov, P. (2025). Machine learning-driven prediction of accompanying droplet structures based on primary droplet shape. Physics of Fluids, 37(4), 042019. https://doi.org/10.1063/5.0268853 IF(2023): 4.1

- Hashemi, A., Ares de Parga-Regalado, A. M., & Ryzhakov, P. (2025). Data-driven analysis of droplet morphology in inkjet systems: Toward generating stable single-drop regimes. The European Physical Journal Special Topics. (accepted 2025). IF(2023): 2.6

- Narváez-Muñoz, C., Dialami, N., Guerrero, B., Carrión, L., & Medina, E. (2025). Electrohydrodynamic manipulation of droplets in confined spaces: Impact of geometric eccentricities and material properties. The European Physical Journal Special Topics. (accepted 2025).

- Antonelli, N., Aristio, R., Gorgi, A., Zorrilla, R., Rossi, R., Scovazzi, G., & Wüchner, R. (2024). The shifted boundary method in isogeometric analysis. Computer Methods in Applied Mechanics and Engineering, 418, 117228. https://doi.org/10.1016/j.cma.2024.117228

- Narváez-Muñoz, C., Zamora-Ledezma, C., Guerrero, B., Almeida, F., Debut, A., Vizuete, K., & Alexis, F. (2025). The impact of electric fields on rheology and fiber formation in electrohydrodynamics-based manufacturing. The European Physical Journal Special Topics. (accepted 2025).

- Community Engagement

- Nine presentations at international conferences.

- Organization of two ECCOMAS Special Interest Conferences.

- “Inkjet Technology and Beyond” international workshop (Spain, Germany, France, Netherlands + HP) with open-access proceedings on Zenodo:

https://doi.org/10.5281/zenodo.13070936

- Academic Training

- Supervised 1 PhD (in progress), 1 Master’s and 2 Bachelor’s theses in ML-assisted numerical methods.

Videos and visualization materials can be found at

https://www.youtube.com/watch?v=YJVKkNHinf0&list=PLnAxBaozVSd–Nw702samDLLa43-gbF7I&pp=gAQB